DTF (Direct-to-Fabric) Shirt printing uses heat and pressure to transfer designs directly onto fabric, offering superior print quality. This process involves digitally printing on coated dtf paper, layer by layer, then pressing it onto garments. High-quality control tools like high-res cameras and light boxes ensure accurate color and detail. Regular equipment calibration, optimized print settings, and testing on scrap fabric maintain consistent results. Special techniques are required for printing on dark fabrics to overcome opacity.

Looking to elevate your DTF shirt printing game? Mastering quality control is key. This comprehensive guide explores essential tips and techniques to ensure impeccable results every time. From understanding intricate DTF printing processes to equipping yourself with indispensable tools, you’ll learn how to achieve print precision and consistency. Discover expert strategies that transform your T-shirt designs into stunning, durable pieces.

- Understanding DTF Printing Processes

- Essential Tools for Quality Control

- Techniques to Ensure Print Precision & Consistency

Understanding DTF Printing Processes

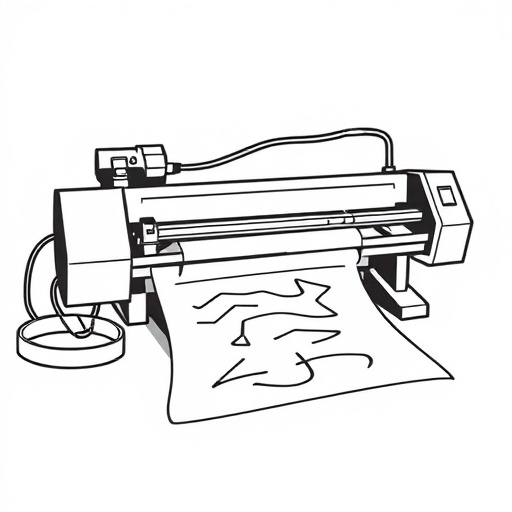

DTF (Direct-to-Fabric) Shirt printing is a specialized process that involves transferring designs directly onto fabric using heat and pressure. Understanding this method is key to achieving superior print quality. The process starts with preparing the dtf heat transfer paper, which is coated with a water-based ink. Designs are then digitally printed on this paper, layer by layer, until the entire artwork is complete.

Once the design is inked on the paper, it’s carefully aligned and pressed onto the garment using a heat press machine. The heat activates the ink, fusing it permanently with the fabric fibers. This meticulous process allows for intricate designs and vibrant colors, making DTF printing a popular choice for custom apparel production, including bulk dft shirt production. Using high-quality dtf transfer sheets ensures consistent and impressive results in every print job.

Essential Tools for Quality Control

To achieve top-notch results in DTF shirt printing, investing in essential quality control tools is paramount. These include a high-resolution camera for meticulous inspection, especially when checking for color accuracy and detail sharpness. Additionally, a reliable light box or contrast screen aids in identifying any print discrepancies, ensuring the final product meets expectations.

For DTF for apparel enthusiasts aiming to create direct to film personalized hoodies, possessing these tools allows for precise adjustments before printing. The best DTF printer, paired with the right equipment, enables you to deliver exceptional quality, catering to diverse customer demands in the competitive market of customized merchandise.

Techniques to Ensure Print Precision & Consistency

To achieve precision and consistency in DTF shirt printing, begin by calibrating your equipment regularly. This includes both the printing software and the heat press machine. Using the right settings for your specific ink and fabric types is paramount. For instance, adjusting the print resolution and pressure can significantly impact the final output.

Additionally, utilizing test prints on scrap fabric before applying the design to the actual shirts ensures accuracy. This process allows you to experiment with different techniques and settings without wasting valuable materials. Remember that DTF printing for dark fabrics requires special consideration due to ink opacity issues. Therefore, choosing the right inks designed for dark garments is essential, coupled with optimizing print techniques to ensure vibrant and detailed results in every batch, enhancing the overall quality of your DTF for apparel production.

DTF shirt printing offers exceptional customization options, but achieving top-quality results requires meticulous quality control. By understanding the DTF printing process, investing in essential tools, and employing precise print techniques, you can consistently deliver vibrant, detailed designs that meet customer expectations. Incorporating these quality control tips into your workflow will elevate your DTF shirt printing outcomes to new heights, ensuring satisfied customers and a thriving business.