DTF (Direct-to-Fabric) shirt printing is a modern, game-changing method for creating custom apparel with vibrant colors and sharp details. Artists must prepare designs in high-resolution vector graphics, use CMYK or spot colors, ensure precise registration, account for print bleeding, and optimize for speed and aesthetic appeal. This technique eliminates complex processes, offers exceptional durability, and is ideal for creating unique, high-quality T-shirts that stand out in the market.

Designing artwork for Direct to Fabric (DTF) shirt printing offers a unique blend of creativity and technical precision. This process requires understanding specific design requirements to ensure high-quality prints on various fabrics. In this article, we’ll guide you through the intricacies of DTF shirt printing, from defining the process to creating visually stunning designs that translate well into print. We’ll also offer practical tips for file formats, image types, and testing to help your artwork shine in the final product.

- Understanding DTF Shirt Printing and Its Design Requirements

- – Definition of Direct to Fabric (DTF) printing

- – Key considerations for designing artwork compatible with DTF process

Understanding DTF Shirt Printing and Its Design Requirements

DTF (Direct-to-Fabric) Shirt Printing is a cutting-edge method that allows for intricate and vibrant designs on textiles. Unlike traditional printing techniques, DTF utilizes digital design files to create high-quality prints directly on fabric, making it a popular choice for custom clothing and merchandise. Understanding this process is key to designing effective artwork for DTF shirt printing.

When creating designs for DTF, artists must consider the specific requirements of the technique. This includes file formats (typically high-resolution vector graphics), color modes (CMYK or spot colors), and the need for accurate registration to ensure the design aligns perfectly with the fabric. The design should also account for potential print bleeding, especially around edges and corners, to avoid visible seams when applied to the shirt. For bulk orders, optimizing the design for speed and efficiency in printing is crucial while maintaining the desired aesthetic, ensuring a seamless and professional finish.

– Definition of Direct to Fabric (DTF) printing

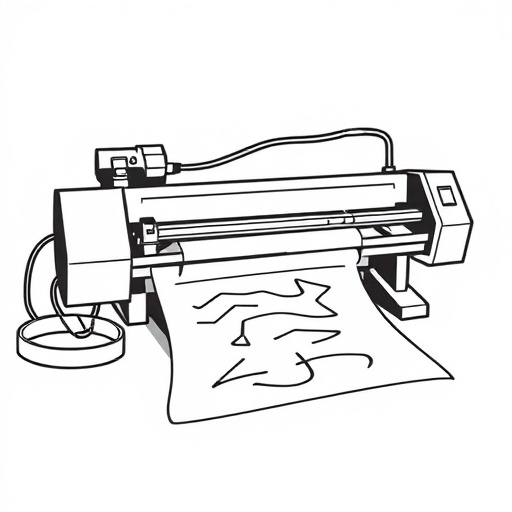

Direct to Fabric (DTF) printing is a cutting-edge technique revolutionizing the world of shirt printing. Unlike traditional methods that rely on multiple layers and complex processes, DTF offers a straightforward approach to designing custom apparel. This modern technology allows artists and designers to apply intricate graphics and patterns directly onto fabric using specialized ink and equipment. By skipping the intermediate steps, DTF printing ensures vibrant colors, sharp details, and exceptional durability on various fabrics, making it an ideal choice for creating unique, high-quality T-shirts and other garments.

Understanding how DTF works is essential when preparing designs for printing. The process involves transferring ink from a carrier sheet to the fabric using heat and pressure. Designers need to follow specific dtf application instructions, ensuring their artwork meets the required specifications. With proper preparation, including file formats, resolution, and color profiles, the final product can showcase stunning visuals with long-lasting quality, setting your DTF custom apparel apart in the market. Moreover, the durability of DTF prints is a significant advantage, guaranteeing that your designs remain vibrant and intact even after frequent washing and wear.

– Key considerations for designing artwork compatible with DTF process

When designing artwork for DTF (Direct to Fabric) shirt printing, there are several key considerations to keep in mind. First and foremost, ensure your design is optimized for the specific material and process used in DTF printing. This includes choosing high-resolution images and avoiding fine details that might not translate well to the final printed product. The goal is to create a design that offers excellent visibility and clarity when shrunk to the size of a shirt.

Additionally, consider the color palette and contrast; vibrant colors typically work best for DTF printing as they can maintain their richness during the heat press process, ensuring durable prints that last longer. Proper spacing and alignment are also crucial, as any misalignment can affect the overall quality of the final print. Remember to check the dtf heat press settings and fabric types supported by your printer to ensure optimal results.