Optimizing DTF shirt printing involves adhering to specific file format, resolution, and color mode standards for error-free results. Using white/light base layers under dark fabric enhances print quality. Streamlining material management through systematic practices and digital tracking minimizes waste and lead times. Advanced press techniques and high-performance heat transfer paper, with custom sheets tailored to fabric types, speed up production while ensuring ink permanence, boosting overall productivity.

“Elevate your DTF shirt printing game with this comprehensive guide! Discover proven strategies to optimize your workflow and achieve unparalleled efficiency. From design setup to material management, we’ll show you how to streamline each step. Learn effective press and curing techniques that ensure top-quality prints every time. Boost productivity, minimize waste, and maximize customer satisfaction with these essential tips tailored for DTF shirt printing professionals.”

- Optimize Design Setup for DTF Printing

- Streamline Material Management Process

- Implement Efficient Press and Curing Techniques

Optimize Design Setup for DTF Printing

Optimizing design setup is a crucial step to enhance efficiency in DTF (Direct-to-Fabric) shirt printing. When preparing designs for DTF printing, ensure your artwork meets the required specifications. This includes using the correct file format (such as SVG or PNG), resolution (300 DPI or higher), and color mode (CMYK). Proper design setup reduces the need for rework and minimizes print errors, saving time and resources.

Additionally, consider the material you’re printing on. For DTF printing on dark fabrics, it’s essential to use a white or light-colored base layer beneath the design. This ensures that the dtf prints are crisp and visible, enhancing overall print quality. Custom t-shirts, for instance, can benefit from this technique, allowing designers to create visually appealing and durable garments.

Streamline Material Management Process

Streamlining the material management process is a key step in enhancing efficiency within DTF shirt printing workflows. For clothing brands looking to optimize their production, this involves implementing systematic practices for sourcing, storing, and tracking print materials like direct-to-film (DTF) films, inks, and blank shirts. Organize and categorize supplies meticulously to ensure quick access during the printing process.

By adopting efficient inventory management techniques, such as just-in-time stocking or digital tracking systems, brands can minimize waste, reduce lead times, and prevent costly stockouts. This streamlined approach allows for smoother transitions between design, printing, and packaging stages, ultimately contributing to faster turnaround times and higher customer satisfaction in the production of personalized hoodies or other DTF printing applications.

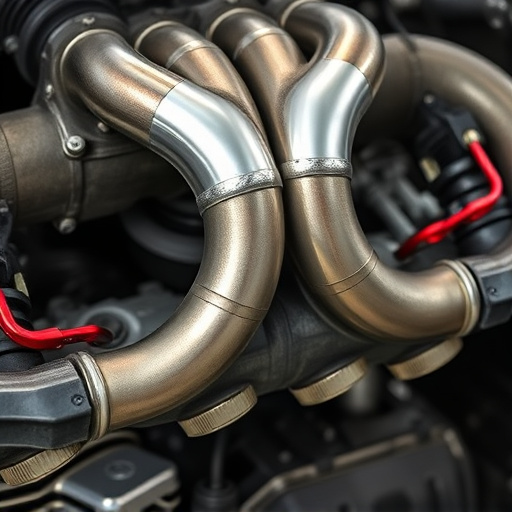

Implement Efficient Press and Curing Techniques

In DTF shirt printing, efficient press and curing techniques are key to maximizing productivity while minimizing errors. The use of high-quality dtf heat transfer paper ensures precise and vibrant dtf prints, allowing for detailed designs that pop on various garment types. Custom sheets for heat pressing designs onto garments further enhance this process by offering a range of materials suitable for different fabric compositions and printing styles.

Optimal curing involves controlling temperature and pressure to set the ink permanently onto the fabric. Faster cure times reduce throughput bottlenecks, enabling printers to handle larger volumes without compromising quality. By implementing these efficient practices, DTF shirt printing businesses can achieve consistent, high-quality results, thereby improving overall workflow efficiency.

By optimizing design setup, streamlining material management, and implementing efficient press and curing techniques, you can significantly enhance the overall efficiency of your DTF shirt printing workflow. These strategies ensure a seamless, high-quality production process, allowing you to meet demand promptly while reducing waste and increasing profitability in the competitive DTF shirt printing market.